How can We Help You?

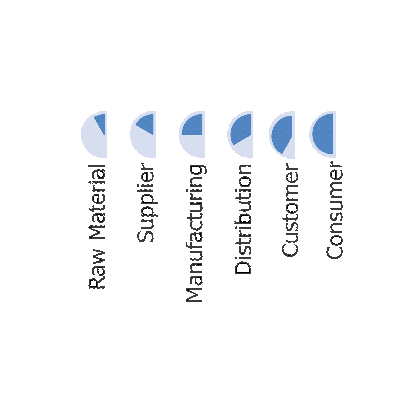

Supply chain Management (SCM) broadly deal with management of Goods and Services from its origin to the consumption. Supply chain management consist of movement of raw material-WIP-finished goods. Supply chain management defined by four basic principle of management

- Planning- What to make? How to make? What to procure? How to procure? How much procure? What to deliver? How to deliver?

- Organising-What to require? When to use? Where? How much?

- Staffing-How many? When? Where? For what time?

- Controlling-How much? At what time? In which quantity?

Systematic and strategic coordination between all business function by identifying and eliminating waste through continuous improvement is a key success factor in supply chain management. Due to Globalization and E-commerce, effective supply chain management is very import to every business organization. On time or before time delivery of Goods or Services to the customer is very important.

Why Lean supply Chain Management?

In today’s fast moving business culture on time delivery to customer with good quality & quantity is very important task of all stakeholders in supply chain. Lean supply chain management help organization to be a competitive in business organization. Lean makes organisations efficient, competent, and excellent in operations by reducing non value adding activity in supply chain and continual improvement through Kaizen. Following are some wasteful activities in Supply chain.

Overproduction: Excess ordering of material, Excess manufacturing of product, Transport over the capacity of vehicle.

Waiting: Waiting for next operation, Trucks sitting idle awaiting their turn at the dock.

Motion: Unnecessary movement of product can be occur within warehouse, within factory or throughout the distribution network, unnecessary movement of people in warehouse.

Over process: Quality inspection, redundant approach and order review at the conclusion of pick/pack.

Inventory: Unnecessary stock of RM/WIP/Finished goods.

Defect: Defective parts translates to supply chain errors of all kinds –from picking errors to incorrect order quantities, Damages during shipping.

Transportation: Complex plant layout, Wrong distribution channel, Reverse supply chain cost added due to faulty delivery of material, Accidental losses.

Benefits of Implementing Lean Supply Chain Management

Delivering the products to the end customer at right place, right time in the right quality & quantity.

Making the flow of the product from raw material to the customer through continuous improvement of supply chain.

Creating the plan to standardize the process and listing out the best practices to be followed.

On time delivery by reducing lead time (Cycle time).

Increased productivity.

Reduce rework and rejection.

Effective fleet management.

Customer satisfaction.

Photos

13 Feb

Photos

13 Feb