Client Feedback

Great work can only come from great partnerships. Here are just a few of the amazing clients that allow us to come to work every day and push our boundaries. And theirs too.

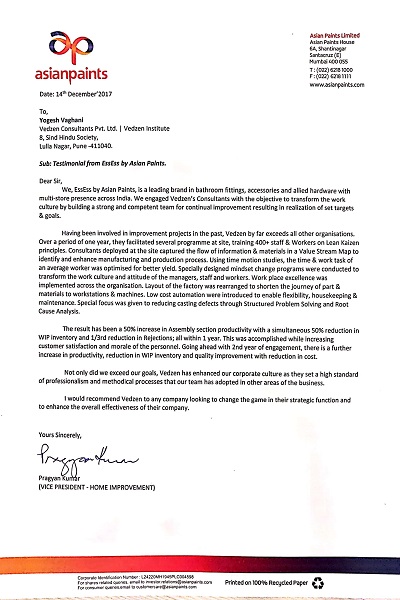

Having been involved in improvement projects in the past, Vedzen by far exceeds all other organisations. Over a period of one year, they facilitated several programme at site, training 400+ staff & Workers on Lean Kaizen principles. Consultants deployed at the site captured the flow of information & materials in a Value Stream Map to identify and enhance manufacturing and production process. Using time motion studies, the time & work task of an average worker was optimised for better yield. Specially designed mindset change programs were conducted to transform the work culture and attitude of the managers, staff and workers. Work place excellence was implemented across the organisation. Layout of the factory was rearranged to shorten the journey of part & materials to workstations & machines. Low cost automation were introduced to enable flexibility, housekeeping & maintenance. Special focus was given to reducing casting defects through Structured Problem Solving and Root Cause Analysis. The result has been a 50% increase in Assembly section productivity with a simultaneous 50% reduction in WIP inventory and 1/3rd reduction in Rejections; all within 1 year. This was accomplished while increasing customer satisfaction and morale of the personnel. Going ahead with 2nd year of engagement, there is a further increase in productivity, reduction in WIP inventory and quality improvement with reduction in cost. Not only did we exceed our goals, Vedzen has enhanced our corporate culture as they set a high standard of professionalism and methodical processes that our team has adopted in other areas of the business. I would recommend Vedzen to any company looking to change the game in their strategic function and to enhance the overall effectiveness of their company.

Pragyan Kumar

VP – Home Improvement, Asian Paints Limited

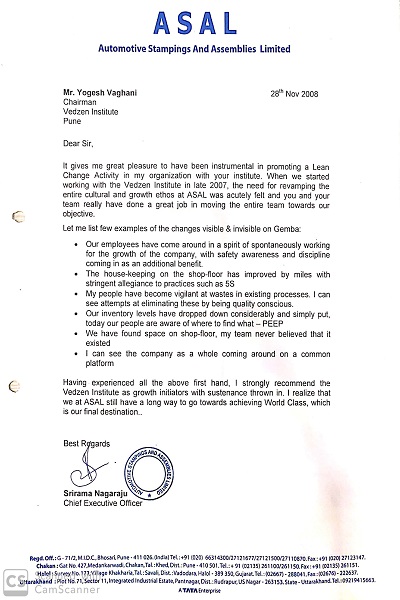

When we started working with the Vedzen Institute in late 2007 s, the need for revamping the entire cultural and growth ethos of ASAL was actually feeling and you and your team really have done a great job in moving the entire team towards our objective. Our employees have come around in a spirit of spontaneous working for the growth of the company, with safety awareness and discipline coming in as an additional benefit. Our inventory levels have dropped down considerably and simply put, today our people are aware of where to find what – PEEP. We have found space on shop the floor, my team never believed that it existed. I can see the company as a whole coming around on a common platform.

Srirama Nagaraju

CEO, Automotive Stamping & Assemblies Ltd,

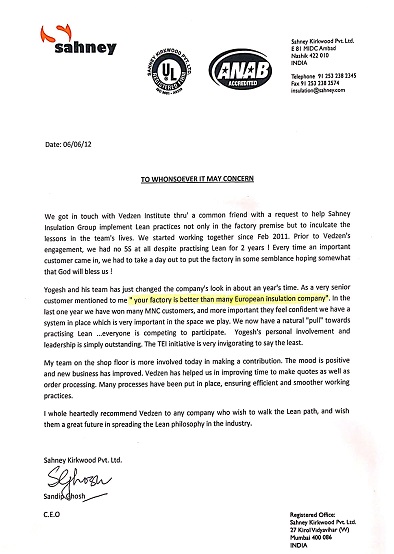

We started our journey in Lean implementation towards achieving world class excellence about 4 years back. The journey thus far has been exciting and extremely fruitful for the organisation. The Vedzen team started with the concepts, worked with the team, including contract employees and begun Total Employee Involvement workshops. I must say the team got energized and enthused to try out new concepts. Waste got eliminated through 5S practices and the team could see the benefit themselves. Several programs were initiated to reduce process losses, develop new products through Lean eye. The users of the processes now take decisions at the Gemba, and this is a great improvement. An external audit of costs revealed a saving of Rs 5.5 million last FY, and this is just the beginning of the journey.

Sandip Ghosh

CEO, Sahney Kirkwood Pvt. Ltd.

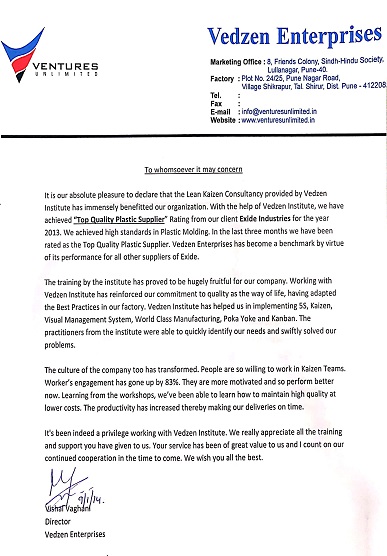

We started our lean journey in 2010 with Vedzen Institute. It is our absolute pleasure to declare that Lean-Kaizen consultancy provided by Vedzen has immensely benefited our organization. With the help of Vedzen, we have achieved a "Top Quality Plastic Supplier" rating from our customer Exide Industries for the year 2013. Vedzen Enterprise has become a benchmark by virtue of its performance for all other suppliers of Exide. It's been indeed a privileged working with Vedzen. We really appreciate all the training & support given by Vedzen.

Vishal Vaghani

Director, Ventures Unlimited

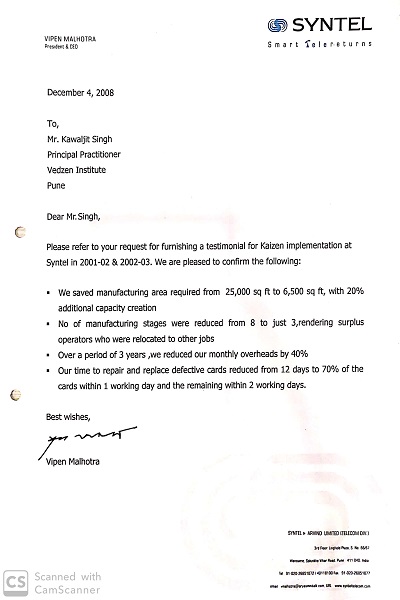

As Vedzen Institutes first customer for Kaizen implementation, I am happy to state that we reaped a rich harvest of benefits. Over a period of 5-6 years, we reduced our manufacturing space from 20,000 square feet to 2,500 square feet while increasing production from 60,000 to 360,000 EPABX ports per annum in the reduced shop floor area. Such was the reduction in space achieved that we sold our old factory to move to much smaller premises, in the process unlocking a lot of capital for alternative deployment. Simultaneously, we recorded a dramatic improvement in turnaround time for repairs & restoration of field defects from 15 days to 70% by the next day and the remaining in 3 days, besides a reduction of 90% in failure rates within and outside the factory.

Vipen Malhotra

President & CEO, Syntel -Arvind Limited (Telecom Div.)

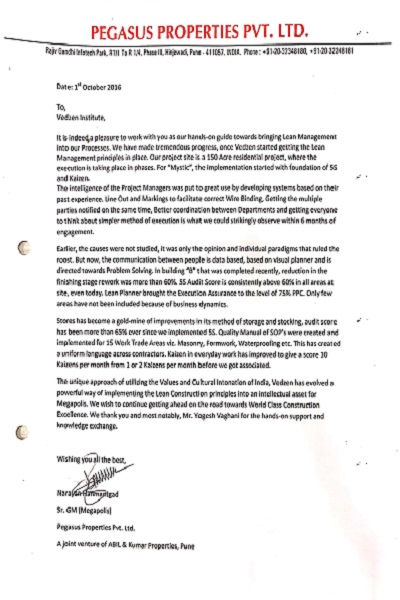

We have made tremendous progress, once Vedzen started getting the Lean Management Principles in place. The intelligence of the Project Managers was put to use by developing systems based on their past experience. Line-Out & Markings to facilitate correct Wire Binding; Getting Multiple parties notified at the same time; Better coordination between Departments and getting everyone to think about simple method of execution is what we could strikingly observe within 6 months of engagement. Earlier, the causes were not studied; it was only the opinion and individual paradigms that ruled the roost. But now, the communication between people is data based, based on visual planner and is directed towards Problem Solving. In building ‘B’ that was completed recently, the reduction in the finishing stage rework was more than 60%. The unique approach of utilizing the Values & Cultural intonation of India, Vedzen has evolved a powerful way of implementing the Lean Construction principles into an intellectual asset for Megapolis.

Narayan Hanmantgad

Sr. GM (Megapolis)

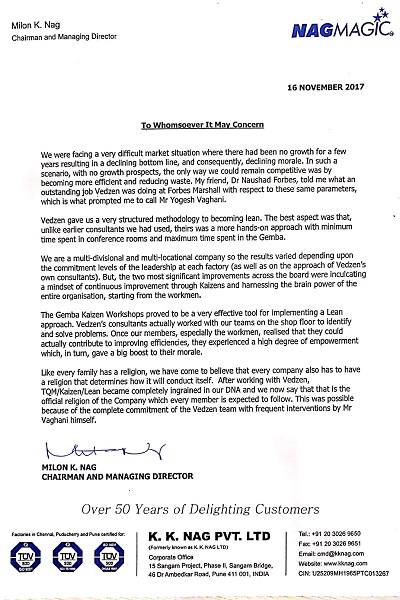

We were facing a very difficult market situation where there had been no growth for a few years resulting in a declining bottom line, and consequently, declining morale. In such a scenario, with no growth prospects, the only way we could remain competitive was by becoming more efficient and reducing waste. Vedzen gave us a very structured methodology to becoming lean. The two most significant improvements across the board were inculcating a mind-set of continuous improvement through Kaizens and harnessing the brain power of the entire organisation, starting from the workmen. The best aspect was that, unlike earlier consultants we had used, theirs was a more hands-on approach with minimum time spent in conference rooms and maximum time spent in the Gemba. After working with Vedzen, TQM/ Kaizen/ Lean became completely ingrained in our DNA and we now say that that is the official religion of the company which every member is expected to follow.

Milon K Nag

Chairman & Managing Director, KK Nag Pvt Ltd.

Vedzen was involved as our Indian partner for implementing workplace excellence through 5S involving all employees in a systematic manner. The idea was to follow the most effective workplace excellence tool, 5S, and the impact work culture positively to boost morale and productivity too. We implemented Kaizen & 5S in all six locations in India through Gemba Kaizen Methodology.

Shrikrishna Tiwari

Operations Dev Manager, Alfa Laval India.

Good Morning Sir, We have received fantastic reviews for yesterday's session from our members.. There have been lot of takeaways from the session.. Very impressive Store Management & Systems/ Processes and Very effective Lean/ Kaizen Methodology for Construction.. We appreciate all the efforts taken to arrange the programme and are very thankful to you and your team for the kindness.. Looking fwd to working with you soon.. Thanks & Regards, Dilip Mittal

Dilip Mittal

Chairman, Credai-Pune Metro

I convey my sincere thanks to Mr. Vaghani and all your Team for your very essential, important, and adequate guidance during Covid 19 situation for the ISO 45001:2018 training & implementation and appreciate your Hard work with dedication as a consultant. It will help our Team to progress the same in a very smooth and systematic way without any further delays.