The pulp and paper industry is one of the oldest and core industrial sector. Paper manufacturing is a highly capital, energy and water intensive industry. It is also a highly polluting process and requires substantial investments in pollution control equipment.

Not all pulp and paper mills or converting operations generate hazardous waste. If, however, your facility uses strong acids and bases, toxic organic chemicals, paints and adhesives, ink, or solvents, the waste associated with using these materials might be hazardous waste. If you generate hazardous waste, you might be subject to Resource Conservation and Recovery Act (RCRA) requirements covering the generation, transportation, and management of hazardous waste. The paper industry is composed of several sectors, including:

- Pulp and paper mills, which produce mechanical, thermo mechanical, and chemical pulps and process these pulps to form paper, paperboard, or building papers

- Converting operations, which manufacture boxes, tablets, and other finished paper products.

Paper Industry Value Chain

CHALLENGES FACED BY THE INDUSTRY

Operations: The challenges faced by the Paper Mills in the operations front can be broadly classified as the following:

- Capacity Utilization

- Energy Costs

- Waste Re-use and Waste Disposal

- Profitability

- Lack of Research and Development

- Lack of skilled man power

- Raw material Constraint

Business Issues

Sourcing

- Wood Source; Govt/ Social / Import

- Seasonal Supply & Cost Variation

- Inventory Management

- Competition from other users (non-paper)

Production

- Product Recipe Adjustment

- Fillers, Chemicals, Coatings compatibility

- Inventory Management for Blending

- Production Plan Adjustments

- Cost of Energy, Steam

Supply chain

- Seasonal Variation in price and demand

- Highly price sensitive user market

- Inventory management @ shelf, keeping the right quantity, grade, GSM & finish a phone call away leads to high inventory cost or lost customers

Market

- Compatibility with conversion

- Requirement for Consistency in quality

- Extremely price sensitive but quality conscious customers

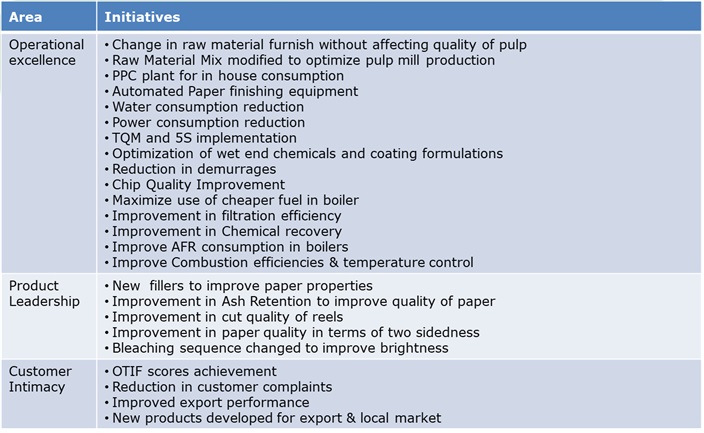

COMMON IMPROVEMENT INITIATVES

WHAT VEDZEN CAN DO FOR THE CLIENT?

Build the basics right and improve the bottom line. Develop and install system that improve planning, Forecasting, Capacity Utilization, increase efficiencies leading to cost reduction and enhanced benefits

Reduce Cost

- Develop & implement best practices of inventory management to ensure elimination & avoidance of obsolete inventory

- Improve house-keeping drastically through one-time mission and ensure sustainability so as to reduce wastage & damage to goods

- Implement ‘first-in & first-out’ or other such practices to avoid wastage & damage of goods

- Ensure appropriate utilization of transportation system through improved planning & coordination

Improve efficiency

- Implement 5S system thoroughly to ensure quick retrieval, storage & handling of goods

- Conduct Value Stream mapping to identify bottlenecks and improve various process centers

- Reduce vehicle turnaround time and thus increase utilization

- Improve material handling & movement through improvement of processes, better upkeep of equipment, SOPs, training & improved awareness

Improve asset utilization

- Conduct capacity utilization studies, bottleneck identification studies and propose measures to optimize utilization

- Conduct studies & analysis to clearly identify areas requiring capacity enhancement through investments and

- Clearly identify areas where idle capacity exists and improve utilization through improved sales & marketing

- Bring about cultural changes in employees ensuring more utilization of human resources

Optimize Inventory

- Develop & implement best practices of inventory management to ensure elimination & avoidance of obsolete inventory

- Improve house-keeping drastically through one-time mission and ensure sustainability so as to reduce wastage & damage to goods

- Implement ‘first-in & first-out’ or other such practices to avoid wastage & damage of goods

Improve awareness and motivation of employees

- Bring about cultural changes in employees ensuring more utilization of human resources

Comments / 0