Last month, I could visit a medium-scaled PVC fittings manufacturer in Pune, which is engaged in this business for the last 15+ years

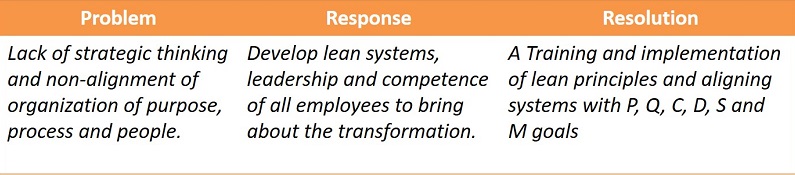

The organization wanted to implement lean practices with the objective to create a clean & safe environment, better quality, productivity, safety, and human growth at a plastics manufacturing facility. Since the customer demand & order projection has been much good, they want to develop lean systems to enhance customer satisfaction, improve productivity, reduce throughput time, utilize space, and reduction in inventory in order to fulfillment for customer requirements on time & in full quantities.

We went to shop-floor & observed the following:

- Poorly organized workplace - 5S is not in place

- High inventory on the shop floor, WIP, BOP, and FG “More of a warehouse than a factory”

- More than 50% of space is utilized in storage (Raw material, WIP, bought out component, waste e.g., grinding, finished goods.

- The Batch production system with a supervisor has most of the time for the day in firefighting.

- Material handling is a big issue because there is no space for the movement of material.

- Inventory in each process was scattered – in fact, spread out across the shop floor.

- No space for handling the material as gangways are blocked with WIP

- The maximum area in the shop floor was occupied by Scrap (Lumps, unwanted material, M/C Parts, etc.)

- Awaiting decisions on Obsolete Raw material & Packaging material related decisions (Awaiting decisions)

- Very high Grinding material on the shop floor. No proper place for storage. No account of the usage of grinding material.

- Plant locations are not defined properly for example BOP parts, Packaging material, Work in progress (WIP), Mold Storage & Machine & Mold Maintenance area, etc.

- Frequent Breakdowns in Injection molding machines

- Visual boards are not at the shop floor to plan & trace production

- Overproduction due to high Changeover time for molds

- SOPs & Work instructions are missing in most of the processes

- Top management most of time & energy loss in managing problems

- The shop floor is not marked & visual factory

- High truck loading time

It starts with reorganizations! A place for everything and every useful thing in its place: If somewhere you have to keep it, then, might as well keep it in a specific place. ‘Anywhere or only here’ both take the same time to keep a thing but the time of retrieval, only here’ is economy of effort. People waste 12% of their time for searching. Humungous loss in a lifetime.

Cleaning with meaning – you don’t only see but notice the abnormalities and take steps to rectify by nipping at the bud stage. Autonomous maintenance….

“When I see it, I will believe it,” is a useless paradigm. Only when you believe in it, you will see it is the truth. You will get to see what you really want to see. As you think all day long, you become. The way you see the problem is the problem. Life is a mere external manifestation of your internal thought process. So, you don’t need new horizons. You just need the right spectacles with which you can see the existing horizons. The way you see life becomes life.

And one of those mental spectacles that are leading the world in every sphere is the collective conviction of human intelligentsia: “There is a better way, always …the way, an effective way an innovative way, a creative way, a better way of life.

‘Minimum effort producing maximum results’ or Keeping things simple

Error proofing. Anything that repeats must be systemized with a checklist or an SOP. When the logical sequence of what’s repetitive is committed to paper, when paper or technology does all remembering and your mind is free to think, that’s economy of effort.

After every mistake, correct the system that allowed the mistake: systematic error management will ensure that there is no repetition of mistakes.

On project completion, audit the loopholes that allowed things to go wrong and correct the system. Turn mistakes into learning opportunities. We cannot avoid mistakes but we can certainly stop the repetition of mistakes through “Systematic Error Management”.

The “Lean” approach starts with the customer and is focused on retaining only those processes that contribute value from the perspective of this end-customer. Only activities that the end-customer is actually willing to pay for are considered to be true value-added activities. Everything else is waste and should be reduced or eliminated.

Lean manufacturing is the process of eliminating all forms of Waste (Muda) from operations and processes through continuous improvement.

It’s about being highly efficient and effective in every endeavor, so that lot more can be done. It’s about making the maximum with the minimum that’s available. Fewer resources, minimum inventory, quality right the first time, zero error, and zero breakdowns.

During our Gemba walk, it was observed people are highly motivated, energetic & cooperative & management is open for improvement. People are ready to share their ideas on what can be done better. What we felt could be improved

The common thread across organizations is missing so create a vision, values, and goals to achieve the vision will play an important role. Right or wrong a map is needed with long-term aspirations plus short-term expectations:

- Mindset change is the important factor to start with any improvement, People should first agree & work as a cohesive team.

- “All we are doing is looking at a timeline from the moment the customer gives us an order to the point when we collect the cash. And we are reducing that timeline by removing the non-value-added wastes ~ Taiichi Ohno, Toyota Production System; 1978

- Lean Layout planning to optimize space

- Online packaging of items on molding machine itself to reduce the WIP

- Visual production planning & monitoring system to be set in identifying bottlenecks and to provide a common platform for developing a communication system

- Systematic arrangement - Place for everything & everything in its place to reduce floor space & standardization

- Problem-solving & root cause analysis for deviation in the standard

- SOPs to be put in visual form at all work station

- Setup time reduction SMED system to reduce changeover time to take frequent changes in products & reduce WIP.

- Total Productive Maintenance - Autonomous maintenance (TPM- AM) to improve machine availability

- Inventory management

- Kanban system (pull) to reduce WIP inventory.

- Frequencies for Scarp shifting, Obsolete material decisions, etc. by mentioning in SOP’s & control plan to make it happen on set frequencies.

If you happen to see the above observations in your organization, we hope you will take appropriate corrective & preventive actions. I would love to receive your feedback & suggestions

If you think that there's more that can be done in the current condition. Please write to me at yiv@vedzen.com

Comments / 0