The word buzzing around in the industry is Smart Manufacturing, also dubbed the fourth Industrial revolution or Industry 4.0. Smart Manufacturing is set to revolutionise agriculture, energy, transportation and other industrial sectors akin to what computers did decades back to media, retail & finance. Ithas already begun producing disruptive companies like Flipkart, Paytm and Big Basket which have redrawn the industry boundaries changing the basis of competition.This technological wave will bring unprecedented opportunities and risks equally for business and society.

The Rise of Smart Machines

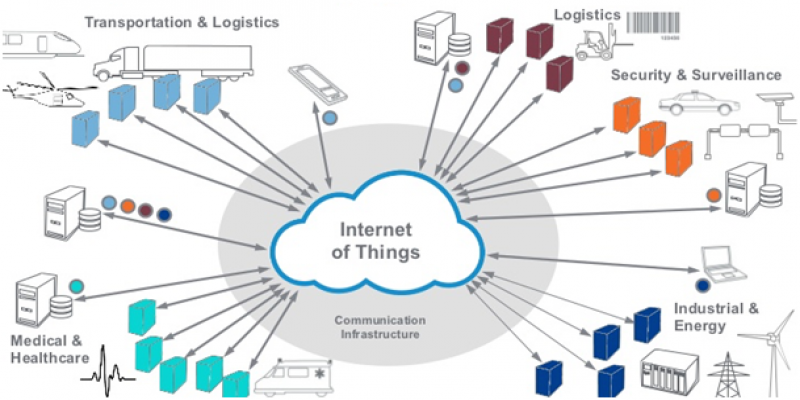

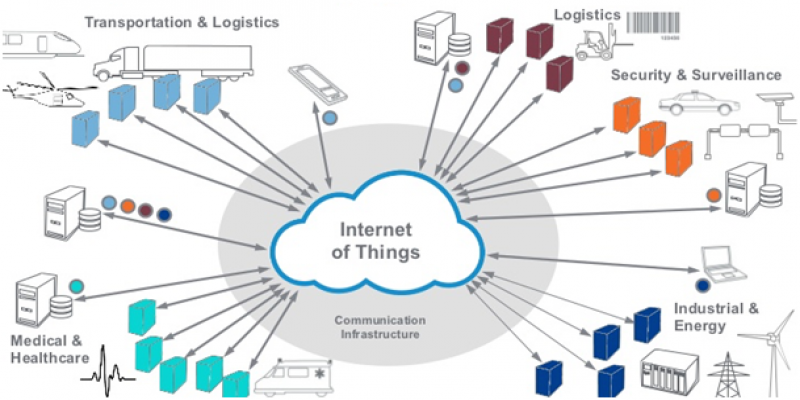

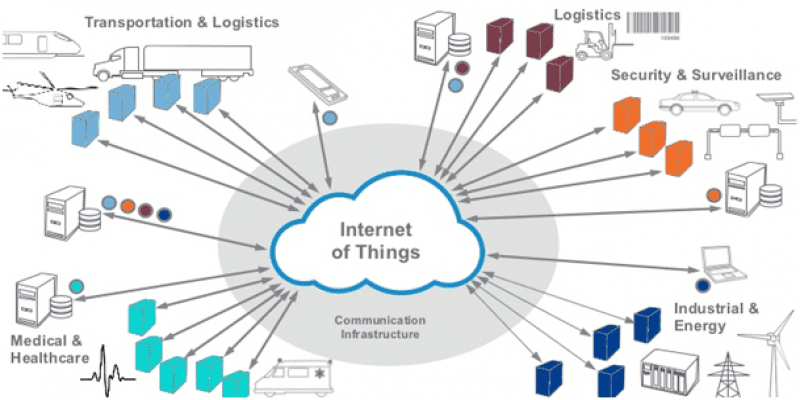

It is anticipated that, by 2020, 50 billion devices will be connected on the internet. The global reach of the internet has enabled direct control of physical world, i.e. machines, factories, transport etc and the infrastructure that define modern world.Simply put, Internet of things (IoT) is all about connecting devices internet to exchange information and data. The IoT is a giant network of connected "things" and the relationship will be between people-people, people-things, and things-things.

Smart Manufacturing is a continuous improvement process across the manufacturing value chain from product development to delivery. It is the current trend of automation and data exchange mostly in manufacturing technologies. Gone are days when PLCs, relays and timers were used to control machines, its processes and outcomes. The people, strategies and equipment working in the industry when connected on the internet is called Industrial internet of Things (IIoT).

The Industrial internet of things makes use of Operations technology to build a responsive customer management and service acumen capability. It unites the industrial system with the power of computing, analytics and new levels of connectivity permitted by the internet. The primary targets of a manufacturer are apparently to improve overall asset performance and to prevent or minimize unscheduled downtime. With the arrival of IIoT, data exchange and analysis in real time, is helping organisations to increase production efficiency, improve execution and optimize performance through advanced analytics. The data exchange reveals the secrets of a machine and help predict, prevent and contain and abnormalities.

A survey conduct by ARC advisory, a leading technology research and advisory firm for Industry and infrastructure reports that the primary drivers fuelling the adoption of IIoT are:

The Industrial Internet of Things can help an organisation in various ways:

- Predictive Maintenance – Sensors can be placed in the machines which communicate with each other and send data to centralized servers for analysis. This helps in Production Performance Analysis, obtaining Machine Status, diagnosing abnormalities etc.

- Inventory Management – Single point view of assets, WIP, inventory, supply chain is provided through real-time identification and tracking of parts/ components/ assemblies.

- Production Traceability – Systems consume and accumulate raw data online which can be used to adjust production machinery and optimize production when any component – speed, temperature, and humidity deviates from acceptable limits.

- Innovation – can be encouraged to bring in solutions and develop ideas that solve problems at the workplace. By enabling Engineers to use smart devices for sourcing and analyzing data in real time abnormalities can be predicted at the earliest and solved.

- Efficiency –is bound to touch skies when problems can be predicted, decisions are taken faster so that solutions are implemented end to end

- Connect & Collaborate – with people at work or on the move, any time to support more intelligent design, operations, maintenance and higher service quality and safety

The Industrial Internet of things (IIoT) is still in a nascent stage where crucial matters remain to be answered. High initial investments, lack of skilled people, Interoperability and data ownership and security are some of most pressing problems which need to be overcome for successful implementation of Smart Manufacturing.

First Hand Industrial Examples

- At one of our client construction site in Hinjewadi, we were able to digitise the daily forms and formats onto a Tab. Tab was designed not only for recording the daily statistics but also as a treasure trove of all the GFC (Good For Construction) Drawings. It had the SOPM (Standard Operating Manual) of all the Construction Activities happening on site. Engineers found this so effective in measuring and analysing the performances of different contractors, shifts, cross-functional reference and quality of construction done.

- At one of the swanky hotels in Hinjewadi, we found a unique table top placard. It had buttons for sending signals directly to the wrist watch worn by the respective waiter for the table. I can at least thank him directly, not to talk about the other options like Water, Next Order and Packing Ready. The Waiters would take the order directly on a small tab pad, which sent the order directly onto the display board of the Kitchen. An Automatic Queuing Application made them promise the delivery time accurately.

- At one of the Automobile suppliers, the storage bins were designed to display the weight of the material. The moment the material weight went down a certain reorder value, the Kanban signal would straightaway go to the supplier for sending the right material for replenishment.

We, at Vedzen, have been helping organisations for the past two decades in becoming World Class Organisation. We optimise processes; enhance leadership capabilities to make organisations better than what they are today. We align business strategy and build people’s commitment to the organisational goals in the age of Smart Manufacturing.

Comments / 0