The collaborative planning system is Lean Construction tool widely used in the construction industry. It consists of an overall schedule with milestone. To achieve the milestone, everyone from foremen to the manager is involved in planning so it’s called collaborative planning and everything is planned ahead so it is also known as pull planning. The collaborative planning system is a team-based activity in which everyone is responsible to achieve a milestone by reducing process constraint. The collaborative planning system consists of the following steps:

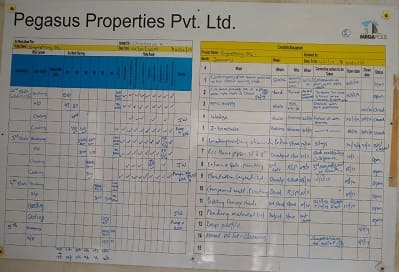

Reverse Phase Scheduling (RPS): Phase schedule is a link between work structure and Production. Purpose of phase scheduling is effective integration and coordination of consecutive operations. RPS developed by a team consisting of all last planners. RPS is useful to identify the trigger point of the next activity.

Six Week Look ahead Plan (SWLA): This is a tool for workflow control in the look-ahead schedule. This indicates kind of work to be done in future.

Weekly Work Plan (WWP): What should be done? What can be done? What will be done? What Did? What learn? These are the key terms in a weekly work plan. WWP is based on Six weeks look ahead to plan.

Percentage Plan Completed (PPC): Can be calculated by the number of activity completed divided by the total number of planned activity. To achieve higher PPC dedicated the last planner with lean tool implementation are required.

Root cause analysis (RCA): As the first week completes we find variance from WWP and PPC. We use RCA to identify the causes of variance and made the necessary improvement in the system.

Visualization: Increase visualization by Signs and labels around the site. Performance measurement and action chart. Safety, schedule, Quality board.

Daily Huddle Meeting: Two-way communication is the key to the daily huddle meeting. Daily huddle meeting should be completed within 30 Mins.

5 S: It is a very important tool in lean management. It is based on the visual workplace. 5S describes “A place for everything and everything in its place within required quantity”.

Vedzen is a group of lean practitioner successfully implementing The collaborative planning system at Megapolis which is the biggest township in Pune. We are implementing Lean construction at Megapolis to build a lean culture at the construction site which helps us to reduce delays in the construction project, reduce the cost associated with rework and rejection due to improper planning. Effective utilization of resources develops lean leadership, it brings lean thinking in construction projects, visual management on construction site to prevent from miss-communication and mistake.

Why one should adopt the Collaborative Planning System:

- To reduce project execution or improve productivity

- To reduce project cost

- To increase the reliability of workflows

- For a better quality of working methods

- For better communication of stockholders

- To improve supply chain integration

Comments / 0